What is Pattern Grading in Pakistan & How It Improves Fit and Reduces Returns

Ever felt stuck trying to grade patterns when sewing traditional outfits or uniforms?

Does the inconsistency in sample sizes, from sample 32 to sample 40, leave you frustrated and cost your business time and money? That problem isn’t uncommon in Pakistan’s clothing and garment industry. What if I told you there’s a structured solution, pattern grading, that standardizes sizes, saves you rework, and delivers consistently accurate fit across the board?

Pattern grading in Pakistan, when done correctly, transforms your sample pattern into a full-size range with a precise technical method. It means fewer returns, happier customers, and higher productivity. In this blog, I’ll walk you through what pattern grading is in Pakistan, how it works step‑by‑step, what benefits it brings to small makers and large factories alike, and how to get it right. You’ll see real local examples and clear guidance so you can apply pattern grading in Pakistan with confidence and clarity.

What is pattern grading in Pakistan?

Pattern grading in Pakistan refers to the method of taking one base pattern, often the sample size, and increasing or decreasing it systematically to produce a full size range (e.g., 28, 30, 32, 34, 36 … up to 44 or more). It’s not about free‑hand guesses or trial and error. It’s a technical process that uses grading rules based on body measurements, style ease, and consistent proportion changes. In Pakistan’s garment industry, pattern grading in Pakistan is the backbone that allows tailors, designers, and manufacturers to scale from a single fitting sample to a full collection of sizes for production.

Why pattern grading matters here

- Uniform fit across sizes: Customers expect consistent fit from small to large. Pattern grading in Pakistan ensures shirt shoulders, sleeve length, waist shaping, and front lengths scale correctly.

- Reduces returns and remakes: Graded patterns reduce sample errors. Less sampling means fewer costly remakes, which is critical in low‑margin operations.

- Saves time and labor: Once grading rules are set, pattern grading in Pakistan speeds up size range creation and eliminates repetitive manual redrafting.

- Professional output and exports: Export houses demand accurate grading. Pattern grading in Pakistan aligns with international size spec sheets and quality standards.

Understanding the grading basics

Base size pattern

You begin with a well‑fitted, perfected size sample (often size 34 or 38, depending on the brand). Pattern grading in Pakistan always starts from this base size.

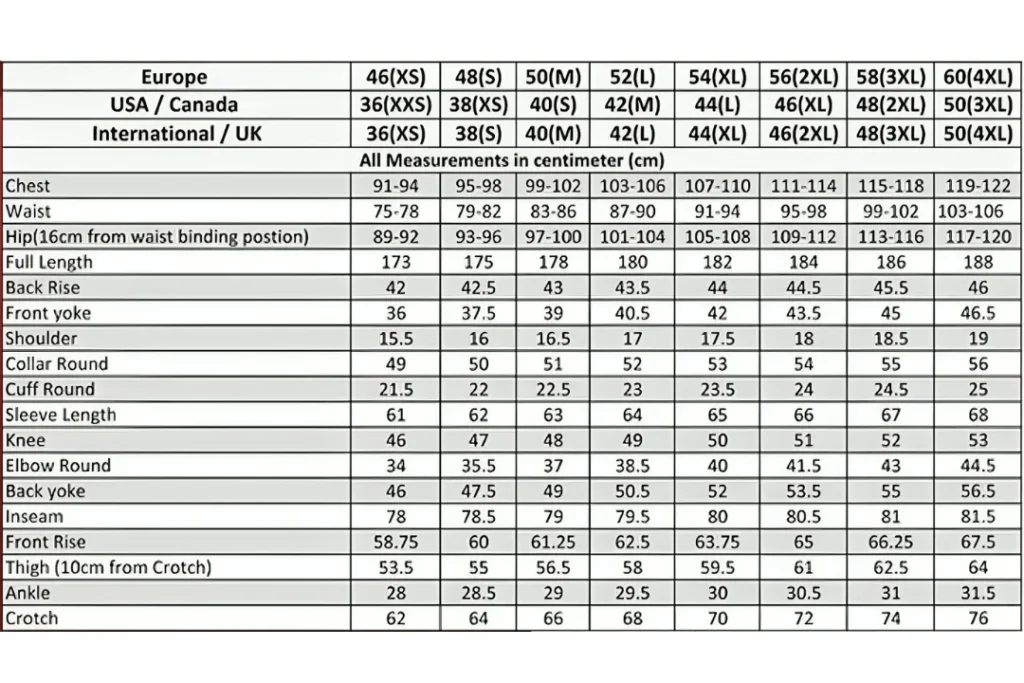

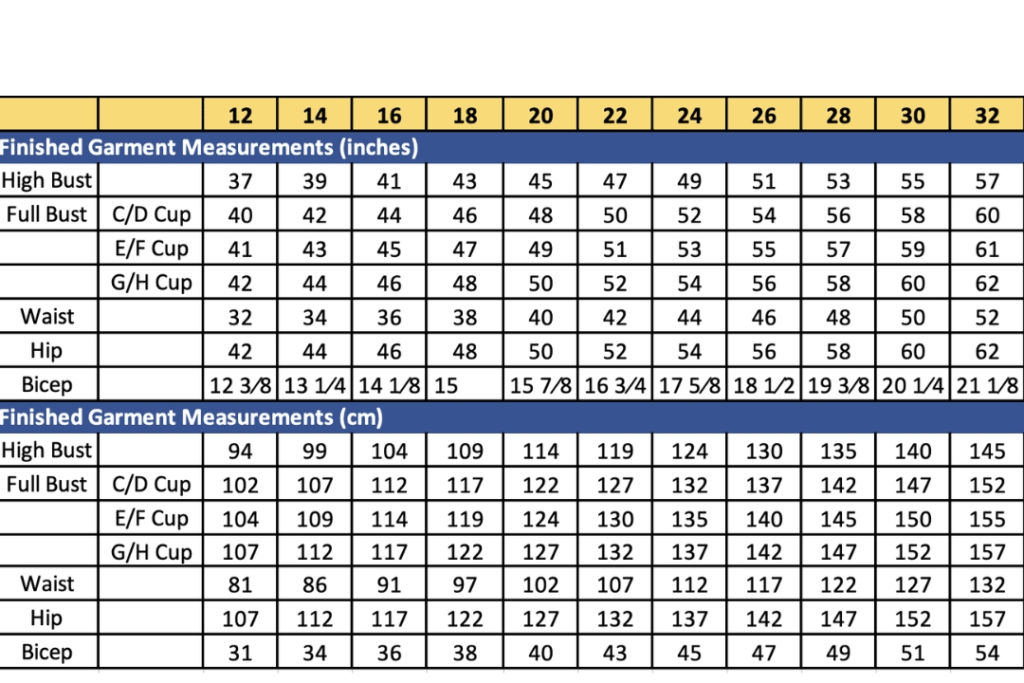

Measurement charts and grading increments

You maintain a standard measurement chart for your brand, for example, garment bust increases 1˝ between sizes, shoulder width increases ½˝, and length adds about ⅜˝. These increments, your grading rules, are essential inputs into pattern grading in Pakistan.

Grading method: manual vs digital

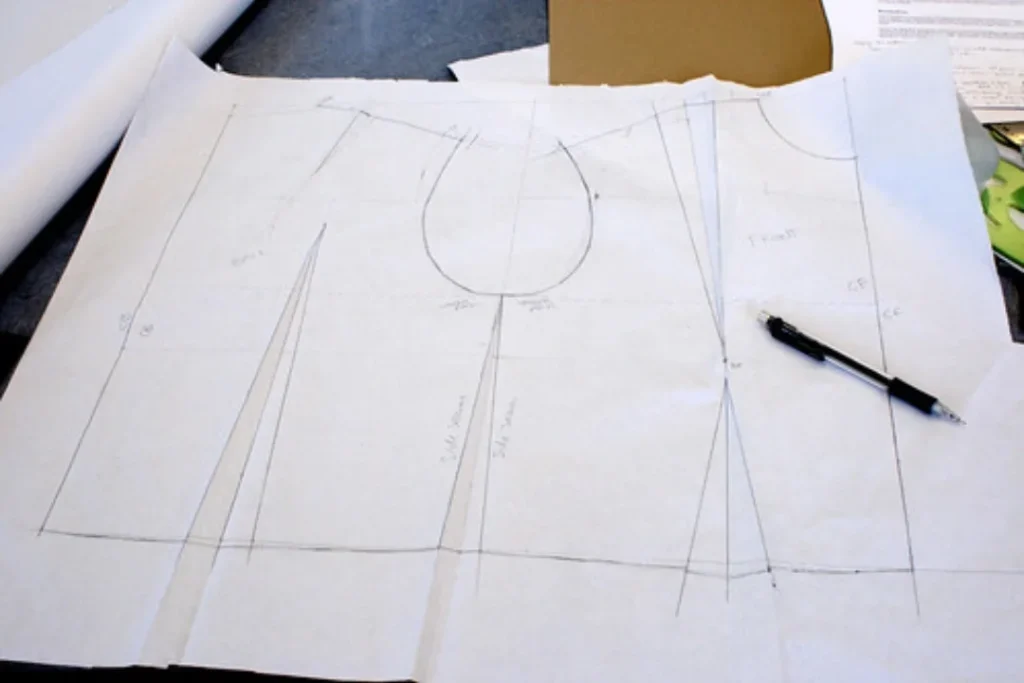

- Manual (paper): Points on the base pattern are shifted outward by defined increments (e.g., bust 2 cm per size). Pattern grading in Pakistan manually demands precision rulers, French curves, and strong drafting skills.

- Digital (CAD): Software like Gerber, Lectra, AccuMark, or Inkscape with plugins can apply grading rules instantly. In Pakistan’s factories, digital pattern grading in Pakistan speeds scalability and consistency.

Types of grading systems

- Proportional grading: Scales pattern uniformly from center points, useful for simple garments.

- Segmental grading: Applies different increments to each body part (shoulder, chest, waist), the most common in pattern grading in Pakistan for tailored designs.

- Combination grading: Mixes both systems for complex styles or special fits.

Step‑by‑step: How pattern grading in Pakistan typically proceeds

Finalize the base size pattern

Ensure seam allowances, ease, darts, and technical marks are correct. This base is the foundation for the pattern grading process in Pakistan.

Prepare a grading rule set

Create a table: SIZE → measurement increments (e.g., bust +2 cm, waist +1.5 cm, length +1 cm). This grading rule set guides pattern grading in Pakistan across the range.

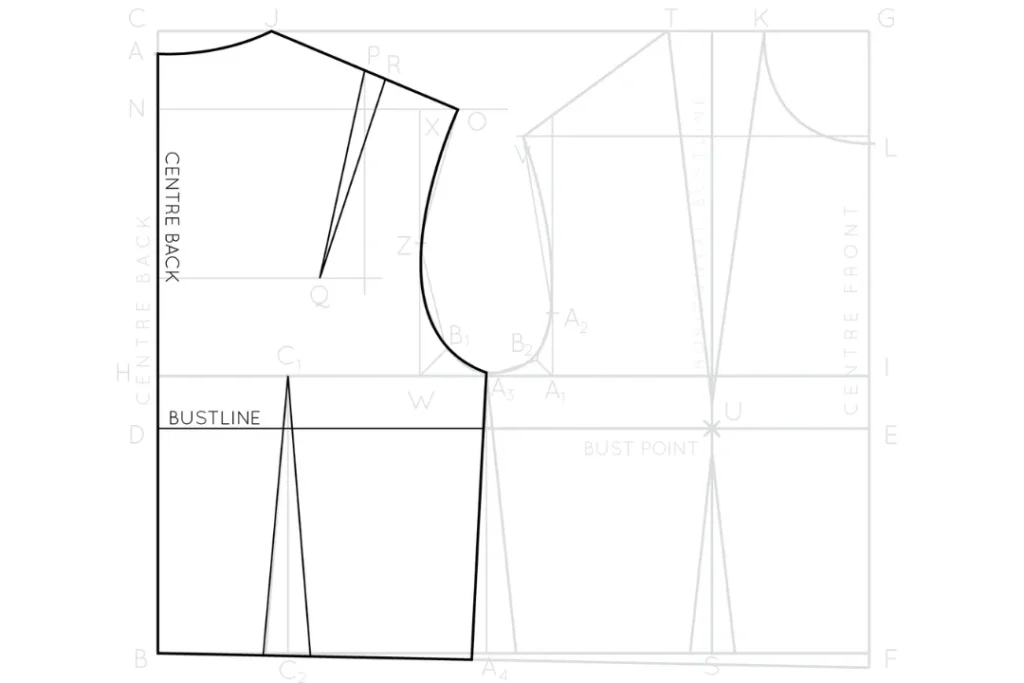

Mark grading points

On your pattern, mark key control points: shoulder tip, bust point, waistline, hemline, sleeve cap, etc. In pattern grading in Pakistan, these are used to shift the pattern reliably.

Apply increments

Shift each grading point outward or inward, depending on size. For each size step, apply the grading rule, shoulder +½ cm, chest +1 cm, etc., maintaining proportion. Pattern grading in Pakistan becomes predictable and mechanical at this stage.

Redraw connecting lines

After shifting, redraw necklines, side seams, sleeves, darts, smooth curves, and straight edges. Pattern grading in Pakistan requires craftsmanship in redrafting.

Check and compare

Place graded sizes over one another to ensure consistent shape changes. Check the sleeve fits across sizes. Pattern grading in Pakistan includes quality control at this stage to avoid distortions.

Real‑life applications in Pakistan

Home‑based tailors and boutiques

Many local tailors draft patterns by eye. Introducing pattern grading in Pakistan, using even manual rulers and simple measurement charts, can yield professional consistency, repeatable sizing for regular clients, and reduced fitting sessions.

Small-scale fashion startups

Startups designing lawn suits or pret collections benefit significantly. By investing in pattern grading in Pakistan (even using basic PDF grading tools), they can produce lines that fit diverse body types across Pakistan and beyond.

Mid-size factories and export houses

These rely on CAD pattern grading to meet specific export specs (EU, UK, US size charts). Pattern grading in Pakistan at this level aligns with global quality standards, reduces wastage, and supports bigger order volumes.

Tips and best practices for successful pattern grading in Pakistan

Start with accurate body measurement surveys

Collect reliable sizing data from target customers or use standard industry size charts in Pakistan.

Use proper ease allowances

Over‑or under‑ease can ruin fit at larger size gradings. Pattern grading in Pakistan must respect garment ease (relaxed, fitted, loose).

Train on segmental grading

It gives better control, different parts grow differently (bust more than shoulder).

Consistently test on real garments

Don’t rely solely on paper. Sew sample pieces across sizes to confirm fit. Pattern grading in Pakistan becomes evidence‑based with physical feedback.

Maintain grading tables and documentation

Keep your grading increments documented for repeatability and brand consistency. Pattern grading in Pakistan is only scalable if you record and use your own rule sets

Consider digital tools if volume demands

Investing in CAD tools pays off quickly if producing multiple size ranges in bulk. Pattern grading in Pakistan digitally speeds up production and reduces error.

Common challenges and how to solve them

Fit distortions in larger sizes

Solution: Reduce increments on sensitive areas like the neckline and armhole; segmental grading helps. Pattern grading in Pakistan takes finesse: not all areas scale equally.

Lack of a standard size chart

Solution: Develop your own through customer measurement feedback and adjust over time. Pattern grading in Pakistan improves with data-driven size tables.

Inconsistent ease across styles

Solution: Set defined ease types per style (e.g., fitted kurta vs relaxed trouser) and adjust grading increments per ease. Pattern grading in Pakistan works best when tied to the garment's purpose.

Manual errors and human fatigue

Solution: Check every shift with overlay or digital backup. Double-check critical points. Pattern grading in Pakistan demands precision, especially when done repeatedly.

Why mastering pattern grading in Pakistan is a game-changer

- Better brand consistency: Your sizes fit the same from batch to batch. Pattern grading in Pakistan creates a reliable sizing identity.

- Chain efficiency: With graded patterns, marker planning, and bulk cutting become streamlined. Less time wasted, fewer mix‑ups. Pattern grading in Pakistan drives operational productivity.

- Scalability: You can expand into new size ranges and markets without reinventing each pattern. Pattern grading in Pakistan is your growth engine.

- Lower sample costs: Instead of sewing each size sample, you sew minimal markers and rely on graded patterns. Pattern grading in Pakistan reduces the sampling budget.

- Improved customer satisfaction: Customers across Pakistan, from Karachi to Peshawar, get a consistent fit. Returns drop, referrals rise. Pattern grading in Pakistan delivers better results

Getting started: practical steps for entrepreneurs, tailors & brands

For tailors and small shops

- Begin with one base size and two adjacent sizes (e.g., 32 and 36). Practice manual increments.

- Draw your basic grading chart: bust + 1 cm per size, waist + 0.8 cm, length + 0.5 cm.

- Use simple tools: ruler, grading triangles, French curves.

- Sew a test garment in each size to refine your increments. That’s pattern grading in Pakistan, rooted in real feedback.

For small-scale labels and startups

- Invest in affordable grading software or collaborate with local pattern houses that offer grading services.

- Standardise grading rules for each style type. Keep consistency across your collection.

- Use real-size mannequins or dress forms to review grading visually. Pattern grading in Pakistan becomes intuitive as you see shapes in 3D.

For factories and export units

- Ensure your pattern tech team follows industry grading systems and size charts relevant to export markets.

- Integrate CAD grading into your workflow. Train staff in vector‑based grading, marking, and pattern nesting.

- Regularly audit graded patterns by overlaying digital patterns across sizes.

Case

A small Lahore boutique’s success

A boutique in Lahore used to draft every size separately for popular kurta designs. This led to inconsistent fit, wasted time, and client complaints. They implemented pattern grading in Pakistan by drafting a perfect size 36, establishing grading rules (+1 cm bust, +0.7 cm waist), and manually grading sizes 30–42. They sewed test pieces, made minor tweaks, and over three months, knocked production time per batch by 40%, reduced returns by 60%, and standardized fit across their regular clientele. Their consistent size range gave them the confidence to take larger orders. Pattern grading in Pakistan was their turning point.

Local resources to learn pattern grading in Pakistan

- Pattern and garment technology institutes in Karachi and Islamabad often run short courses in manual and CAD grading.

- Some export-oriented factories and technical centers offer grading training to local designers.

- Online workshops and manuals exist in Urdu and English, search “grading pattern course Pakistan” or check vocational training centers.

- Join local sewing clubs or Facebook groups where tailors share grading charts and tips. Peer learning accelerates proficiency in pattern grading in Pakistan.

Final thoughts

Pattern grading in Pakistan is not a luxury; it’s a necessity for any maker or brand that wants consistency, growth, and credibility. It transforms a single expertly drafted sample into a full line of well‑fitting sizes that reflect your brand’s identity. Done right, it cuts waste, increases your speed to market, and improves client satisfaction. And best of all, you can begin with simple manual tools and scale into CAD as your volume grows.

You’re not just copying sizes, you’re creating a system. A system that, once in place, works for you. Pattern grading in Pakistan gives you control over style, fit, and profit. Start small, build your grading rules, test your garments, and refine as you go. I guarantee: your business, your clients, and your sanity will thank you.

Frequently asked queries (reframed in everyday terms)

Every brand and style differs, but a standard rule in Pakistan is roughly +1 cm at bust, +0.8 cm at waist, +0.5 cm for length per size step. Fit preferences and fabric impact these numbers, so adapt pattern grading in Pakistan to your needs.

Yes, manual paper grading works well for small batches, just be precise with your increments and use transparent overlays. Digital grading only becomes essential when you handle high volumes or export demands. Starting pattern grading in Pakistan by hand builds skill before investing in software.

Even paper patterns should be labeled and filed by size. If you grade digitally, save each graded file with size metadata and grading rule notes. Clear organisation prevents mix-ups and makes repeated pattern grading in Pakistan easier.

Apply smaller or customized increments near curves. Use segmental grading so curves grow at slower, controlled rates. Pattern grading in Pakistan relies on thoughtful point distribution, not just uniform scaling.

Children’s sizes often need tighter increments (e.g., 0.5 cm per size), and body proportion changes faster between sizes. Adjust your grading rules accordingly when pattern grading in Pakistan for juniors or kids.