Quality Control Forms in the Apparel Industry for a hoodie in Pakistan for Consistency and Buyer Trust

What is the outcome if a minute sewing mistake, a skipped step, or a missing label is not noticed during the production process?

A single hoodie may pass through without anyone noticing, but these errors, when multiplied across hundreds of pieces of clothing, can lead to order cancellations, financial losses, and brand reputation degradation. This is the concealed issue that most factories in Pakistan deal with: not only the lack of proper documentation but also inconsistent checks. The apparel industry undergoes all kinds of problems, such as delays, returns, and unnecessary costs, due to the lack of structured monitoring.

That is the place where Quality Control Forms in the Apparel Industry are so significant in the case of Pakistan, as they come as a solution. These forms shouldn’t be perceived just as paper sheets; rather, they are the indications of every hoodie production stage, right from the inspection of raw fabric to final packing. Without depending on factory verbal instructions or assumptions, the latter gets a clear, documented system that prevents errors before they happen. And in today’s competitive global market, this is not only helpful but also essential.

Why Quality Control Forms Matter in the Apparel Industry of Pakistan

Peshawar’s textile industry contributes a lot towards the country’s exports, the hoodies are one of the most demanded categories. Buyers from Europe, the USA, and the Middle East not only expect quality but also on-time delivery and compliance with international standards. A little quality erosion can result in rerouting of shipment, loss of confidence, and potential customer contacts.

Quality Control Forms in the Apparel Industry

A hoodie made in Pakistan is one of the items in the production line for which Quality Control Forms are used to ensure that the teams doing production do not miss even the smallest detail. These forms help to uncover problems at the initial stages, lower the amount of rework, and maintain the same quality throughout all the pieces. Such forms become very important, especially when one is dealing with bulk hoodie orders, where materials, stitching, zippers, and printing have to be the same as per the buyer’s specifications.

Key Areas Covered by Quality Control Forms

When we talk about Quality Control Forms in the Apparel Industry a hoodie in Pakistan, we’re not referring to just one template. Multiple forms exist, each designed for specific checkpoints in the production process. Let’s break them down:

1. Fabric Inspection Forms

- Measure shrinkage, color consistency, and GSM (grams per square meter).

- Record defects like holes, stains, or weaving irregularities.

- Verify fabric matches the approved sample.

2. Cutting Inspection Forms

- Track the accuracy of hoodie panels.

- Ensure cutting markers match the approved patterns.

- Note any fabric wastage or misaligned prints.

3. Stitching Quality Forms

- Evaluate seam strength, thread tension, and alignment.

- Record skipped stitches or loose threads.

- Ensure hood, sleeves, and body panels align perfectly.

4. Printing & Embroidery Inspection Forms

- Check logo placement and sizing.

- Verify colorfastness and durability.

- Document alignment with buyer-approved artwork.

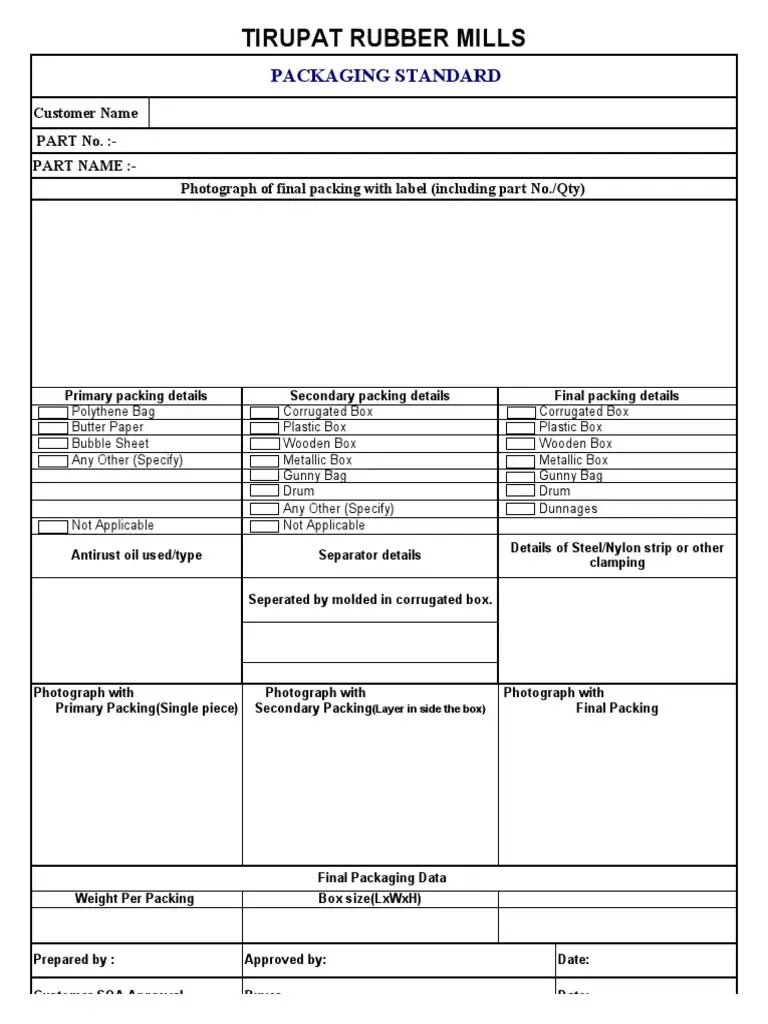

5. Final Packing Forms

- Confirm correct labeling, barcodes, and size tags.

- Ensure that folding and polybag packing follow export guidelines.

- Note carton quality and accurate quantity per box.

By implementing these checks, Quality Control Forms in the Apparel Industry a hoodie in Pakistan minimize rejection risks and keep buyers satisfied.

How Quality Control Forms Improve Hoodie Production

Every apparel factory in Pakistan knows that meeting deadlines and delivering flawless hoodies is not optional; it’s mandatory. Quality control forms act as a bridge between the production floor and management, offering several benefits:

- Consistency across batches – No matter how many hoodies are made, each unit meets the same standard.

- Early problem detection – Defects are caught before garments move to the next stage.

- Buyer trust – Documented quality assurance gives international buyers confidence.

- Cost reduction – Less rework means lower production costs and faster delivery.

- Compliance assurance – Many buyers demand proof of inspections, which forms provide.

For export-driven factories, these advantages are the difference between securing long-term contracts and losing them.

The Role of SOPs in Hoodie Quality Control

Standard Operating Procedures (SOPs) are the backbone of every successful apparel production unit. Without SOPs, forms lose their value because teams may interpret instructions differently. A hoodie factory in Pakistan might use Quality Control Forms in Apparel Industry a hoodie in Pakistan, but unless those forms follow SOPs, the process remains incomplete.

For example:

- An SOP may define how many hoodies to inspect per batch.

- It may explain how to classify defects as minor or major.

- It may instruct workers on how to handle rejected pieces.

When SOPs and quality control forms work together, factories gain a structured, reliable system. This ensures that every hoodie leaving the factory aligns with international buyer expectations.

Real Challenges Pakistani Factories Face

Let’s address the reality. Not every factory in Pakistan has a strong quality control system. Common issues include:

- Skipping inspections to save time.

- Relying on verbal approvals instead of written documentation.

- Inconsistent training of workers.

- Lack of standardized forms for hoodie production.

These practices often result in rejected shipments. International buyers rarely accept excuses. They expect compliance, documentation, and transparency. That’s why adopting Quality Control Forms in the Apparel Industry a hoodie in Pakistan is no longer optional. It’s a survival strategy.

How Hoodie Factories Can Implement Effective Quality Control

If you’re running or managing an apparel unit, here are practical steps to start:

- Develop Standardized Forms – Create inspection forms for every stage, from fabric to packing.

- Train Workers – Ensure line supervisors and workers understand how to fill forms correctly.

- Conduct Random Audits – Cross-check forms to confirm they reflect reality.

- Use Digital Tracking – Move beyond paper by adopting simple digital tools for recording.

- Collaborate with Buyers – Share documented inspections to build transparency and trust.

By following these steps, Quality Control Forms in the Apparel Industry, a hoodie in Pakistan, will no longer be a theory but a practical reality that strengthens your production line.

Global Buyer Expectations and Pakistani Compliance

International buyers don’t just look at the final hoodie; they examine the process. They want proof that each piece meets safety, durability, and design requirements. For instance:

- US buyers may check compliance with ASTM standards.

- European clients may demand REACH compliance for fabric chemicals.

- Middle Eastern buyers may insist on modest design standards.

With Quality Control Forms in the Apparel Industry, with a hoodie in Pakistan, factories can present documented evidence during audits. This not only meets buyer expectations but also improves credibility in competitive markets.

Why Hoodies Demand Extra Attention

Unlike T-shirts, hoodies have multiple components: hoods, drawstrings, zippers, pockets, ribbed cuffs, and sometimes embroidery or printing. This complexity increases the chances of errors. A loose zipper or uneven hood can ruin the entire product.

That’s why Quality Control Forms in the Apparel Industry a hoodie in Pakistan are even more critical for this category. They ensure every part is checked and documented. Factories that specialize in hoodies often design forms tailored to this product alone, reducing the risk of missed defects.

Future of Quality Control in Pakistan’s Apparel Sector

With global buyers demanding faster delivery and higher quality, Pakistan’s apparel industry must evolve. The future lies in digital quality control systems where forms are filled out through tablets or smartphones and uploaded instantly. This eliminates delays and human errors.

Factories that adopt advanced Quality Control Forms in the Apparel Industry a hoodie in Pakistan will not only survive but thrive. They’ll attract premium buyers who value documented, transparent, and efficient processes.

FAQs

By quality controlling each step (corresponding), the forms help closely monitor the entire production process so that no quality defects are across. In the production of hoodies, where there are a number of components, these forms help to keep the factors of the processes going and reduce the amount of rejected parts.

The answer is No. Lesser factories tend to do without proper documentation, whereas export-oriented ones must ensure the use of Quality Control Forms in the Apparel Industry to meet the needs of buyers in the international market.

The answer is yes. When defects are detected at the earliest stage, they limit the need for reworking and the usage of materials that were of no use, eventually reducing the cost and positively impacting the productivity.

Main points are sewing quality, zipper straightness, fabric durability, print correctness, sticker accuracy, and packaging standard.

Methods include creating regular templates, developing personnel qualifications, performing the inspection, and coordinating the work with an SOP.

Conclusion

Pakistan’s textile industry is at a tipping point when it comes to inspection modes. The standards set by buyers from around the world are so high that factories that are not supported by proper documentation are the ones to lose orders. As one of the most export-oriented products, hoodies should be given special attention.

Implementing Quality Control Forms in the Apparel Industry a hoodie in Pakistan, gives factories the power to control quality at every step, maintain buyer trust, and secure long-term contracts. In a market where reputation decides survival, quality control is not just a process; it’s the backbone of success.