How Automation in Clothing Factories Boosts Work in Pakistan to Improve Speed and Quality

Have you ever noticed that just one small hold-up in production can take crumbs from the entire sales season of a Pakistani clothing brand? Reflect upon it: the collection of Eid is delayed, the summer lawn of the campaign could not be launched on time, or export orders are not being met on time. Then what consequences will there be?

A lot of rupees lost, potential left undeveloped, and the customers who have always been there for you treated with indifference. Here, the clothing industry revolves around stringent deadlines, but traditional techniques are not enough most of the time. Slow stitching, manual checking, and tedious jobs brought in large numbers cause bottlenecks that consume workers’ productivity. The feeling of being constrained is doubled when you see that the international rivals who have already been automated are running the business at lower costs and higher speed.

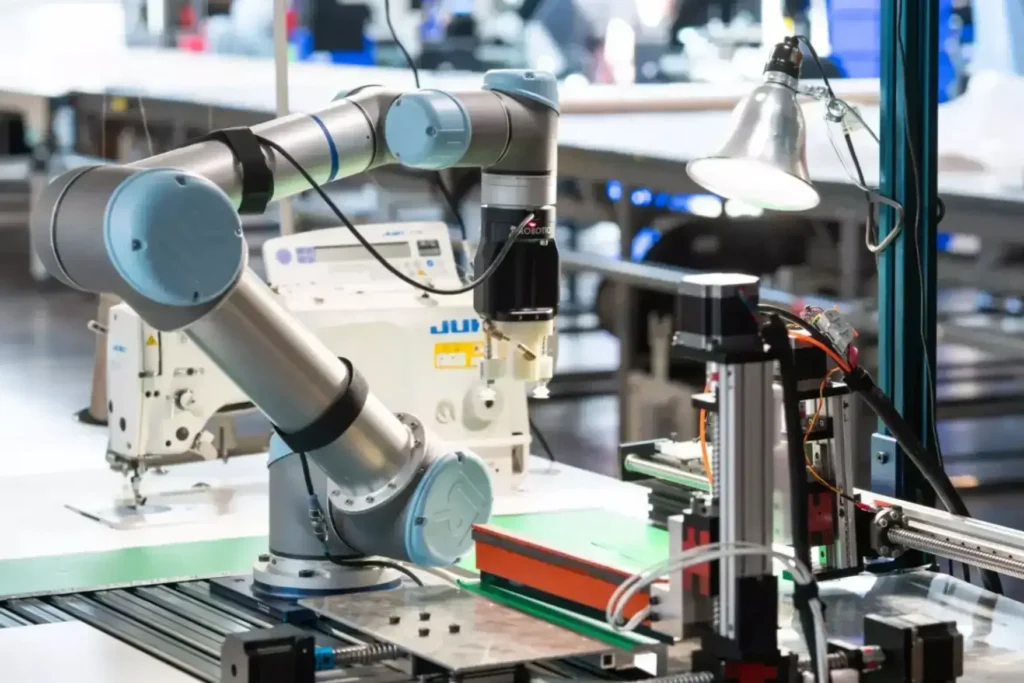

But, what if a different picture is in your mind: a factory in Faisalabad with automated cutting machines, a smart sewing system, and digital quality checking? The situation of orders that were once done in weeks has turned upside down to orders done in days. The workforce has to do less and skilled workers more, and so the factory will have high output with fewer mistakes. This is precisely the information in How Automation in Clothing Factories Boosts Work in Pakistan, not only by the tremendous acceleration of production but by the comprehensive overhaul of the business model towards expansion, sustainability, and global competitiveness.

Why Automation Matters for Pakistan’s Clothing Industry

The textile and clothing industry of Pakistan is the main contributor to almost 60% of the total export income. It is a huge employment provider that caters to the needs of millions of workers, both direct and indirect, and in that way, it becomes one of the most significant sectors of the economy. Unfortunately, a lot of factories are heavily dependent on the traditional ways of working, which negatively impacts the growth of their potential.

As a game-changer, automation comes into the picture. The factory is not eliminated by automation, but the factory workflow is optimized. Meanwhile, machines can perform precision-based, tedious tasks, and workers will be engaged in value-added jobs. As a result, the whole system operates at a level where productivity escalates, waste decreases, and customer loyalty deepens. This is the core of the mechanism by which automation in Clothing Factories Boosts Work in Pakistan

The Current State of Clothing Factories in Pakistan

Visiting the factories, which are small and medium-sized, in Sialkot, Karachi, or Lahore, one would often come across traditional cutting tables, manual embroidery, and hundreds of workers handling stitching lines. These kinds of setups have been the pride of Pakistan for many years; nevertheless, they are no longer adequate to satisfy the increasing demand of international buyers.

In addition to that, these international clients are expecting:

- Delivery to be faster.

- Quality is to be maintained while producing large quantities.

- Efficiency in terms of cost while still adhering to the standards.

Those factories that will not be able to meet these kinds of demands will lose their contracts to other countries like Bangladesh, Vietnam, or China that have already deeply automated their clothing production lines. That is the reason why automation in Clothing Factories Boosts Work in Pakistan, not just a matter of efficiency; it’s a matter of staying relevant in the global supply chain.

Key Areas Where Automation in Clothing Factories Boosts Work in Pakistan

1. Automated Cutting Machines

The automated machines precisely cut hundreds of layers of fabric, which they normally cut manually. This saves the fabric, speeds up the production, and also ensures that the products are of the same size.

2. Sewing Automation

The smart sewing machines that are equipped can do complex stitches and patterns quickly than manual work. While human operators are still needed, automation is used to reduce fatigue and errors.

3. Embroidery and Printing

The computer-assisted embroidery and digital textile printing allow the brands to create complex designs in less time, thereby increasing the possibilities for customization without halting production.

4. Quality Control

Defects are identified electronically through the use of cameras and sensors, and, as a result, only products of the highest quality are allowed to advance. In this way, both the company saves money (the need for which is reduced) and its reputation is protected from being harmed.

5. Supply Chain Management

By using automated tracking systems, the factories are able to keep an eye on their inventories, shipments, and deadlines. In this way, the flow of work in the factory becomes more efficient and less exposed to delays.

These scenarios demonstrate the revolutionary impact of automation in clothing factories in Pakistan, as it manages to defeat the multiple inefficiencies that plague the supply chain, right from the stage of fabric cutting to the stage of final packaging.

Benefits of Automation in Clothing Factories Boosts Work in Pakistan

1. Increased Productivity

In a typical factory, a system can be employed to make more products. In this manner, the factory can easily satisfy the demand of the local and foreign markets in a time-efficient way.

2. Improved Quality

The use of machines reduces the standard variations found in human work; as such, quality is maintained throughout the production, which is also up to international standards.

3. Cost Savings

Despite the fact that automation requires a lot of money to set up, the savings in the form of less waste, quicker delivery, and more orders accepted without being returned make a lot of money in the long run.

4. Workforce Empowerment

Automation doesn’t mean job cuts; rather, it moves workers from doing the same things again and again to doing the supervisory, creative, and technical jobs. This not only upgrades the workers’ skills but also brings more chances of job opportunities.

5. Global Competitiveness

The sellers from the European countries and the US generally prefer the suppliers whose factories have the capabilities for the advanced manufacturing process. The electrification of Pakistani mills will make them stay attractive to the global clientele.

These are the fundamental benefits of automation in clothing factories in Pakistan that make businesses more efficient, workers more skilled, and the country more competitive, which is the real deal about How Automation in Clothing Factories Boosts Work in Pakistan.

Common Concerns About Automation in Pakistan

Some factory owners hesitate to adopt automation, fearing job losses or high costs. But let’s address these concerns realistically:

- Cost Barrier: While the initial purchase of the equipment may be expensive, the government can help with incentives, and the factory can adopt the equipment gradually, which will make the transition less painful.

- Job Security: Workers do not disappear; they change. They can be retrained to be able to do the job that machines cannot, like that of the supervisor, the creative, and the problem solver.

- Cultural Resistance: Every change gets some doubt; however, a complete rejection of the use of technology in your business can lead to losing the market position against those rivals who have committed to it already.

Indeed, this highlights the reasons for managers how adopt automation in clothing factories can improve work in Pakistan. The point is not to change the human workforce, but rather to anticipate what is coming next.

Case Study Insights

- Bangladesh Example: The improvement of the whole machinery approach is what enabled Bangladesh to move up the ladder, to kick off Pakistan, and thus become the global leader in garment exports. Also, the delivery rate of the factories has hit a record speed, simultaneously with the lower defect rate.

- Pakistan’s Emerging Leaders: The wealth of the large-scale Faisalabad and Karachi-based exporters has been the major cause of the automation investments. As a result of this move, the volume of their exports almost doubled, within only a few years, thereby realizing the excellent advantages of the decision.

These real-life scenarios vividly visualize how the implementation of factory automation increases the work volume in Pakistan’s clothing sector, whenever the practice is taken up flawlessly and logically.

The Human Side of Automation

Humans tend to think of machines that simply take the place of laborers, whereas the reality is that they usually help workers to get rid of the monotonous part of their duties. For instance, if a stitching worker performs exactly the same operation for 10 hours per day, can she or he not be easily injured by wear and tear, and get exhausted? In this case, the company might use automation in the repetitive part, and the worker will be responsible for overseeing, managing, or operating several machines, thus he/she will earn a better salary and get more skills.

Moreover, while human resource structures and processes go through a different transformation in the world of factory automation, these are just other ways to display that efficiency is not the only thing that is being achieved; rather, human progress is being made as a result of the same industrial revolution.

Challenges Pakistan Must Overcome

- High Initial Investment: Many small factories do not have enough money to go for major automation.

- Lack of Training Programs: Machines have a limited capacity to do so much; without the necessary skill training, their productivity is bound to fall.

- Infrastructure Issues: Electrical power interruptions and outdated facilities have a very significant effect on the slow pace of adoption there.

- Policy Gaps: Factory owners must not only be given financial incentives but should also be provided with the suitable infrastructure for their undertaking and the right skills and knowledge through awareness and training activities.

Future Outlook: What’s Next for Pakistan’s Clothing Industry?

The future is a combination of both manual and automated work. The use of a complete automated system in all factories may not be possible; however, the employment of a semi-automated system is feasible and has a significant result. The garments sector of Pakistan can proceed towards the realization of its goal by the implementation of the cutting process and the monitoring of quality through automation, while the other areas are being modernized at a gradual pace.

The question is no longer whether Pakistan should automate; it’s how fast factories can adapt before competitors leave them behind.

Final Word

Pakistan’s economy depends heavily on the apparel sector, yet it cannot advance using antiquated practices. Customers want speed, accuracy, and dependability, and there is intense global rivalry. This is precisely how automation in Pakistani garment factories improves work by cutting down on delays, enhancing quality, empowering employees, and assisting manufacturers in meeting needs from around the world.

The question now is not whether Pakistan should automate, but rather how quickly factories can adjust before rivals overtake them.